Menu

Log In

APN Global is a Québec-based growing company looking for solutions to increase its production capacity.

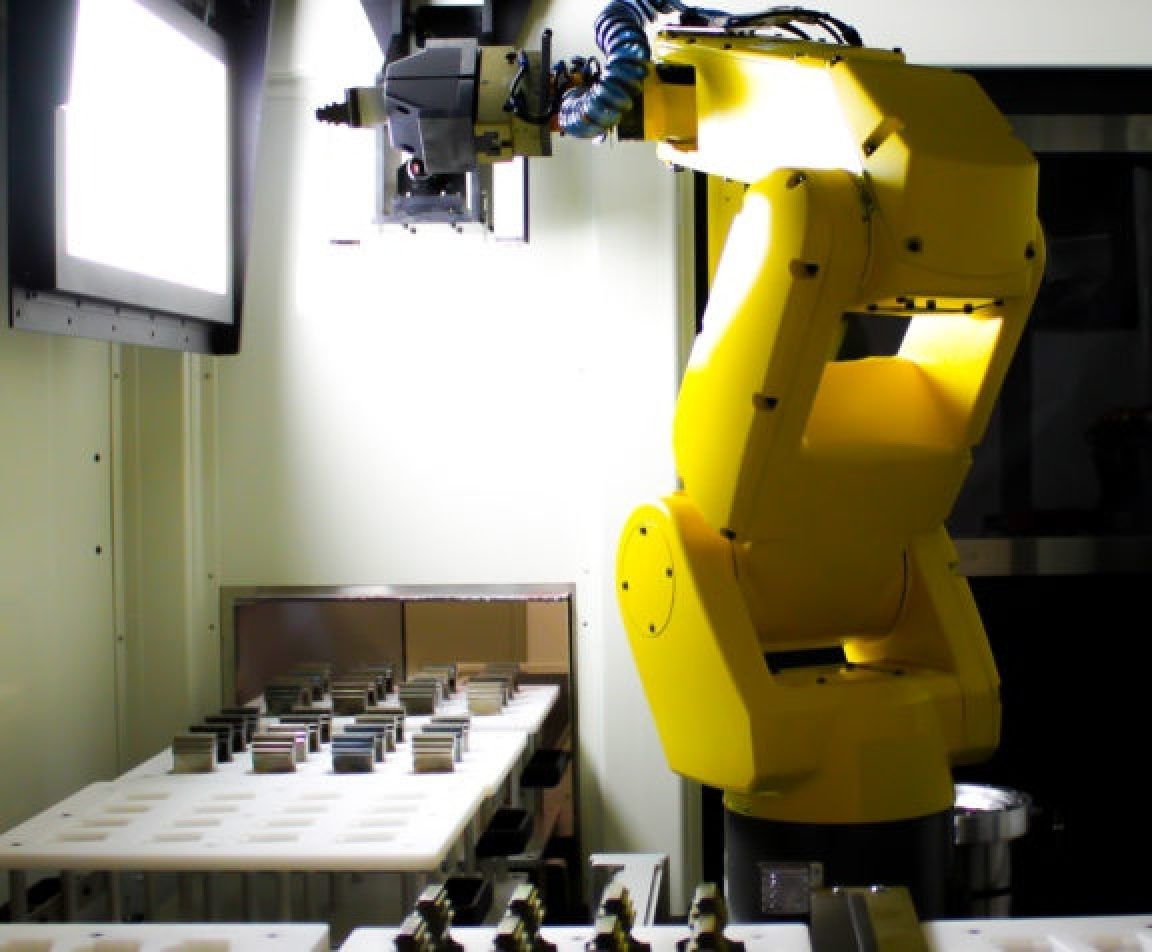

As a pioneer in 4.0 concepts, the company looked to automation to improve its deburring capacity (removal of edges on metal parts).

With the situation of a labor shortage, it is difficult for APN Global to hire manual operators to perform the deburring operation. Training of these operators is lengthy to ensure the quality and consistency their customers expect.

of parts to deburr each year

manual operators for deburring operations working in 2 shifts

working hours per year per operator

Within 3 weeks after the installation of the robotic system at APN Global, the company had programmed and approved the automated deburring of 6 different parts.

This represents around 750 hours of fully automated deburring per year, which is the equivalent of an additional half-resource.

After a short customised training on the BrainWave software, APN Global is now autonomous for the robotic programming adjustment of the other parts in its production. The next goal for APN Global is to increase the automated deburring hours per year, in addition to the work done by its manual operators.

Thanks to the robotic system

Increase 750 hours of deburring per year (and more to come)

To program automated deburring for new parts

William St-Germain, Automation Director