Menu

Log In

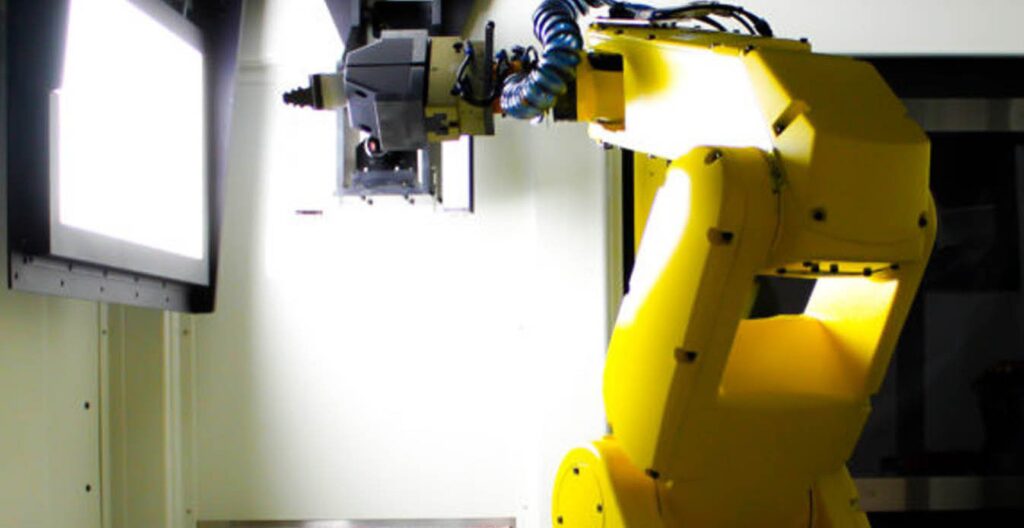

We like to present ourselves as experts in finishing robotic surface and automated visual inspection. We are also proud to tell you that we exist since 1994 and that we have clients all around the world.

However, to put it simply, we are truly passionate about innovation and helping our clients achieve robotic solutions that really work and solve their problems.

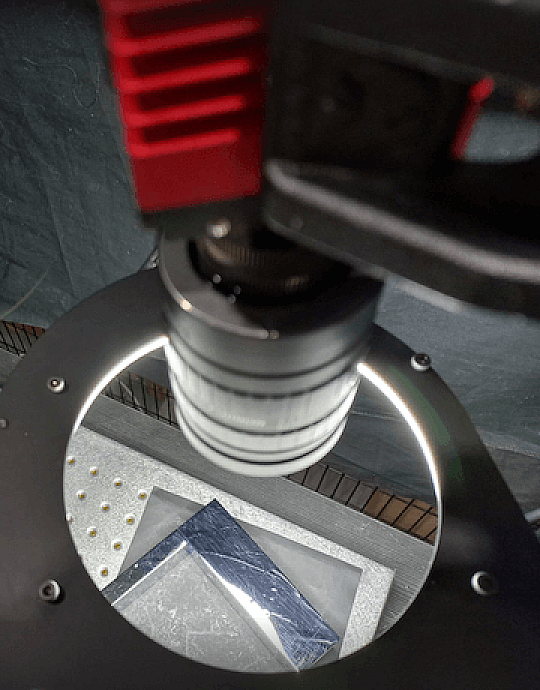

Automate Visual Inspection Operations to Increase Production Output

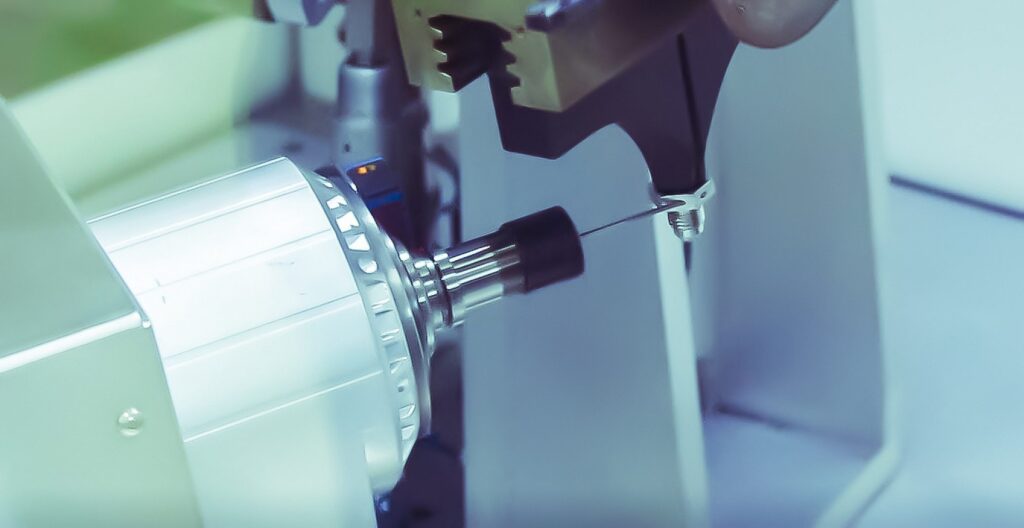

Automation of Deburring Operations Supporting Business Growth